What is this?

Mochem Industrie, for more than thirty years experienced in the field of natural and hard anodizing treatments, is now also offering shoot peening service on aluminum alloy parts.

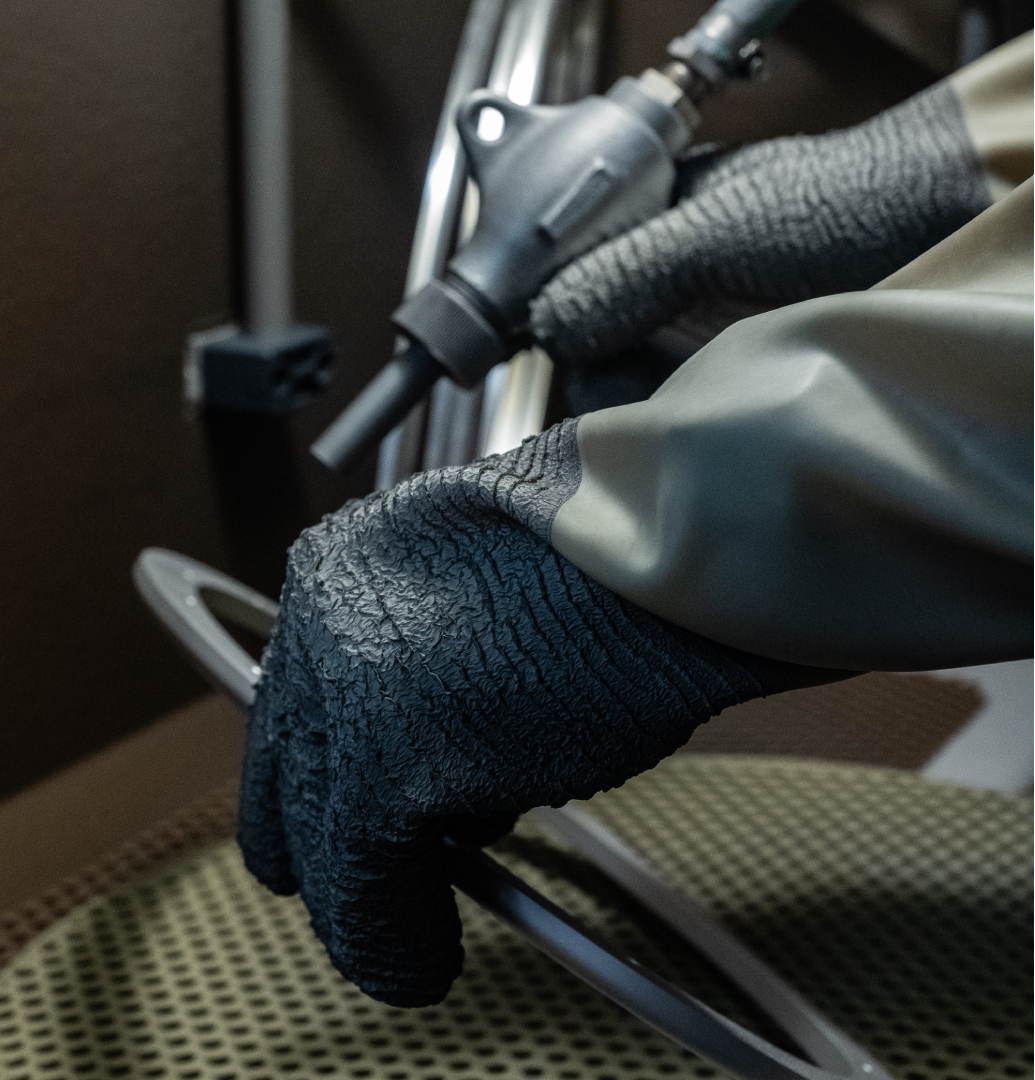

Micropallination (shoot peening) is a surface finishing treatment carried out on mechanical components useful both to improve their performance during fatigue stress and to give them a different aesthetic appearance.

How it works?

Through a vigorous casting of specific parts (of varying geometry and material), it is possible to ensure a slight plastic surface deformation that, in addition to increasing the fatigue strength of the component, succeeds in unifying its surface finish by going so far as to hide all the micro-defects that an aluminum alloy part almost always has.

Before anodizing processes in fact, aluminum, being a soft material, tends to micro-scratch and mark easily during simple handling.

MACHINE

S11 Norblast

Vacuum shot peening machine

MICROSPHERES

B120 / B60 Ceramica

MSV 90-150 Vetro

NEGOTIABLE SIZES

850 x 500 x 500 mm

MSV 90 – 150 Vetro

Using expertly executed shoot peening, Mochem Industrie is able to optimize the surface aesthetic finish, which, being an increasingly sought-after parameter today, gives more value to the anodized material.

Contattaci

Siamo a disposizione per una campionatura gratuita in tempi rapidi

Compila il form sottostante, ti risponderemo il prima possibile.